For printing uses of any shapes, the bleed is 3 mm on each side. The graphic area must extend beyond the cutting line.

Elements cut inside the use must be at least 5 mm away from the external cutting line.

The fit of the print and cutting edges may vary by ±1.5 mm.

The file with the cutting grid should be attached to the print file as the last page in a multi-page file. If files are sent separately, their names must clearly identify the content.

Projects for die cutting (cutting, creasing lines) must fit within a rectangle with a maximum dimension of 300x470 mm.

Bleeds may extend beyond this area.

The minimum required bleed is 2 mm on each side.

The project must include:

The fit of the print and cutting edges may vary by ±1.5 mm.

Milling allows precise cutting of any shapes in a wide range of rigid materials (from large format printing).

Cutting and scoring depending on the processed material is performed using two technologies: knife or cutter. To achieve a precise effect, consider the specifics of processing for the given substrate and apply appropriate markings in the production file.

| Material | Cutting Technology | Minimum Rounding Radius (R) | Internal Vertices | External Vertices |

|---|---|---|---|---|

| PCV 2-3 mm | Knife | 6 mm | Allowed | Allowed |

| Kappa 5 mm | Knife | 10 mm | Allowed | Allowed |

| Kappa 10 mm | Knife | 15 mm | Allowed | Allowed |

| Tusand 10 mm | Knife | 15 mm | Allowed | Allowed |

| Others | Cutter | 4 mm | Not Allowed | Allowed |

Note: Preparing cutting lines not in accordance with the above recommendations may result in jagged edges.

The file with the cutting/milling grid should be attached to the print file as the last page in a multi-page file. If files are sent separately, their names must clearly identify the content.

CO2 laser cutting allows precise cutting and engraving in a wide range of materials within a limited working area.

The file with the cutting grid should be attached to the print file as the last page in a multi-page file. If files are sent separately, their names must clearly identify the content.

File Formats

Cutting rectangular uses to size is done using two methods: manual knife trimmer or circular saw with fine teeth.

This tool resembles a large knife guillotine cutting system. It operates on the principle of a sliding blade that cuts the material with one smooth motion. It is mainly used for precise trimming of thin materials such as paper, foil, thin cardboard, or plastics.

This cutting tool is equipped with a disc with numerous fine teeth. It is mainly used for cutting thicker materials such as composite panels, thicker cardboard, or materials with greater rigidity.

Both methods leave visible marks on the side edges.

If you want perfectly smooth edges, choose diamond milling, which ensures the highest precision and smoothness of finish.

For creasing, perforating, or folding custom projects (not defined in templates), you should:

Unlaminated paper with a weight of 250-350 g/m² may crack on creasing lines. The effect is particularly visible on dark colors. To avoid this, lamination is recommended.

Drilling holes is a bookbinding process in which holes of a specified diameter are made in printed materials. This service is particularly useful for projects such as calendars, tags, labels, catalog cards for folders, or other materials requiring binding or hanging.

To measure the length of a curve line, download the overlay for CorelDRAW™ from our website:

Download file: DDCorelMacro.gms

The overlay works in all versions of Corel starting from CorelDRAW™ 10 onwards.

To add the module to the program, copy it to the ..\Draw\GMS folder located in the folder where CorelDraw™ is installed. With typical settings, it should be: “C:\Program Files\Corel\Corel Graphics 12\Draw\GMS"

In CorelDraw X8, the file should be uploaded to “C:\Users\{username}\AppData\Roaming\Corel\CorelDRAW Graphics Suite X8\Draw\GMS".

Folder naming may vary depending on the version of Corel and the operating system.

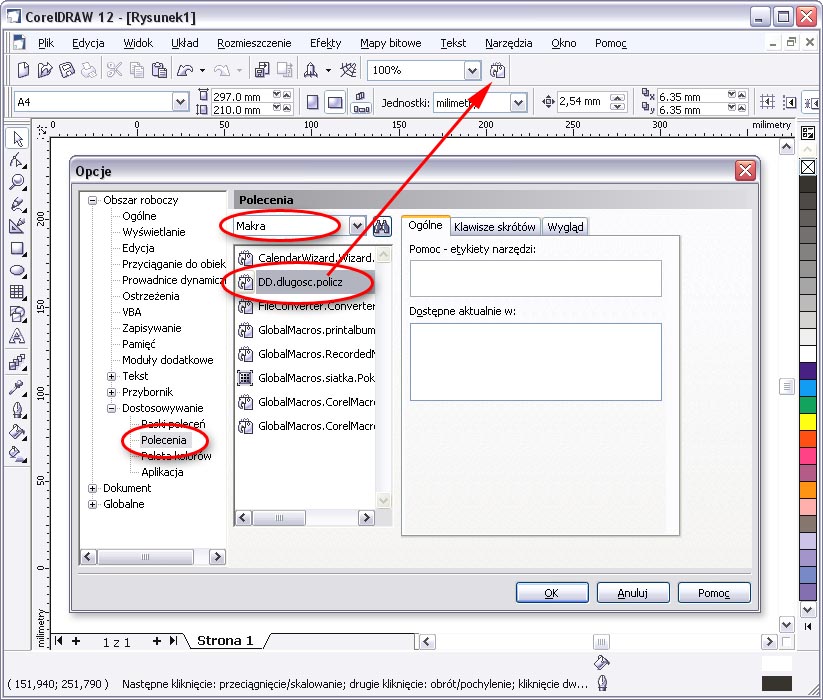

Then, launch CorelDRAW™ and select Tools -> Customization from the menu. The “Options” window should appear on the screen

According to the marked fields in the above figure, select Commands from the list of options, then choose Macros from the drop-down menu. Find the DD.dlugosc.policz macro in the list of available modules. To add a button with our macro to the list of buttons, “drag and drop” the selected macro to the button bar and drop it there. (red arrow in the figure)

To calculate the cutting line length, select all cut shapes and click the newly added button.

If you do not have the appropriate version of Corel, the length can be measured with any program that has functions for measuring curve length. The length should be provided in millimeters.

If there is no appropriate software, you can print the cutting lines on any printer at a known scale and manually measure the line length using a ruler, compass, or thread, then multiply by the known scale factor. This approximate value should be entered into the calculator, and our employee will correct it after checking the length in the program.